What We Do

- Chiller unit - for first time in Mangalore ready mix industry

- Sand sieving system - It filters unwanted particles and impurities from natural river sand and helps produce best quality concrete.

- 24X7 power supply with state grid supply and heavy duty generator back up

- Continuous water supply with adequate ground water supply and storage facility of up to 2 lakh litre capacity.

- 24X7 emergency relief vehicle and mobile quality monitoring service

- Disciplined work ethics

- Weigh bridge

Chiller Unit

Chilling Unit is a unique feature of central mixer unit and we are proud to say we are the only ready mix supplier to install this facility. The chiller unit ensures that water used for mixing is maintained at a uniform temperature of 5° centigrade. This will us help in keeping the concretecool at a temperature of 27° (+ or -2°) for prolonged period. This feature is useful in avoiding shrinkage cracks and other faults during curing process.

The Chilling Unit has a tank capacity of 1500 litres yielding output of 7500 litres per hour.

Mixer Unit

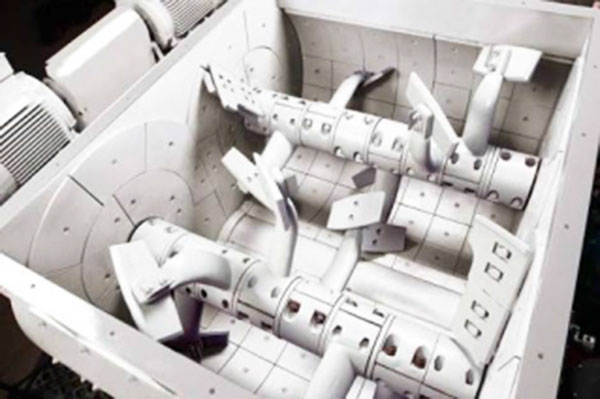

Our central mixer unit comprises of a unique twin shaft mixer with a processing capacity of60 CUM per hour. The plant is suitable for 24x7 heavy duty operation enabling uninterrupted production and supply of high quality readymix concrete.

Twin shaft mixing system involves two synchronized horzontal axes allowing for better uniformity and homogeneity of the concrete mixture. This system is suitabe for producing a wide variety of concrete consistencies, making us an ideal choice for sourcing ready mix concrete for different applications.

Our central mixer is a computer controlled unit ensuring accurate batching and mixng of concrete as per defined specifications.

Weigh Bridge

Our production plant is equipped with a weigh bridge to keep track of all incoming and outgoing vehicular cargo. This weigh bridge is linked with the batching software attached to our mixing unit. All vehicles passing through our gates are weighed and documented for total quality monitoring and transparency in our operations.

Lab Testing

We have well equipped dedicated laboratory facilities for spot testing before, during and after the production process on various parameters. The lab collects samples and maintains documentation of test results for various stages of concrete cycle. Third party referral testing from certified units can also be arranged as required.

Fleet

On-time delivery is a crucial requirement in ready mix concrete supply. We maintain an entire fleet of heavy duty mixer trucks manned by trained personnel who ensure uninterrupted supply of fresh ready mix concrete at the construction site.

Pumps

We have trailer mounted heavy duty 1807/1400 line pump which is capable of continuously pumping liquid concrete to vertically upto 100mts(35 floors). We are one of the few ready mix suppliers to possess such high capacity equipment.

Special Concretes

At IRC Concrete Mix India Pvt. Ltd., we have expertise in making various standard and special purpose products meant for different end applications.

- High grade concrete - This is a standard quality most commonly used commercial grade concrete which is known for offering advantages like speed, finish and economy.

- Self compacting concrete - This is a superior quality concrete which delivers excellent surface finish with no compaction, hence the best choice for complicated structures

- Fibre reinforced concrete - This concrete offers a high degree of cohesiveness, improved resistance to cracking due to shrinkage and long term cost effectiveness.

- Light weight concrete - A relatively light density concrete for non structural application offering high thermal insulation and cool interiors for home or office.

- High early strength concrete - The high early strength of this concrete drastically reduces de shuttering time, provides extended time for placing, finishing and compaction and allows faster project completion.

- Temperature controlled concrete - Keeps temperature rise inside concrete mass under control and enables you to achieve reduced shrinkage cracks and ease of finishing

- Color/Stamped concrete - Get customized shades, textures and colours for decorative finish ideal for exterior applications.

- Permeable concrete - Allows percolation of water, reduces run off and ensures recharge of ground water - best for gardens, pathways and other exposed areas.